Contents

Table of Contents

- Introduction to High-Speed Spindles

- Benefits of High-Speed Spindles

- Applications in Different Industries

- How to Choose the Right Spindle

- Maintaining High-Speed Spindles

- Future of High-Speed Spindle Technology

Introduction to High-Speed Spindles

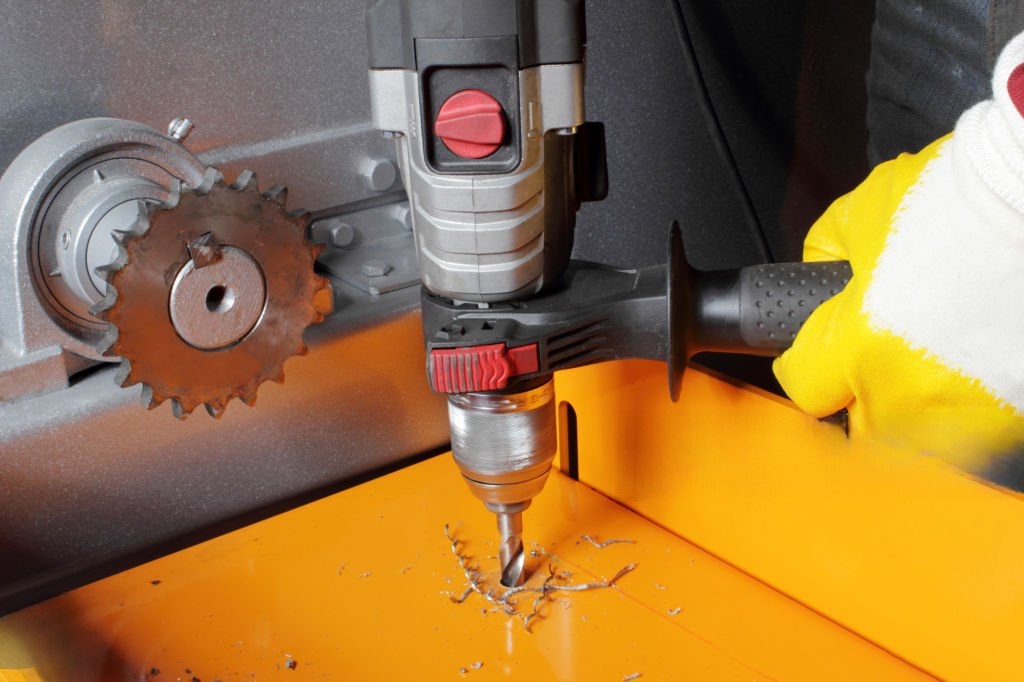

High-pace spindles are a crucial factor in cutting-edge manufacturing equipment, designed to rotate at extraordinarily excessive speeds to allow precision machining. The performance of a high-velocity spindle, consisting of a CNC spindle, helps producers acquire super accuracy and production efficiency, making it quintessential in various business programs.

The evolution of excessive-pace spindles reflects the growing demand for excessive precision and speed in the manufacturing system. These spindles affect the very last product’s high quality and contribute to advanced operational efficiency, which is important in the ultra-modern aggressive business panorama. High-velocity spindles play a greater role in pushing breakthroughs in machine tool technology and placing new standards for overall performance and reliability as manufacturing processes turn out to be extra complex.

Benefits of High-Speed Spindles

Using high-speed spindles can considerably enhance the efficiency and accuracy of manufacturing tactics. According to a file on Machinery News, these spindles can lessen production time and improve the finish high-quality of machined components.

- Increased productivity

- Improved surface end

- Reduced tool wear

Increased productivity is possibly the most notable gain. High-pace spindles allow for faster-reducing speeds, decreasing the time it takes to finish an assignment. This no longer only boosts manufacturing quotes but also enables assembly-tight closing dates without compromising on fines. When manufacturing processes are streamlined, producers can tackle greater orders and improve their ordinary output, leading to better utilization of resources and higher profitability.

Another advantage is a superior floor end. The excessive rotation speeds permit smoother cuts, resulting in a finer end at the final product. This can be specially useful for regions like the automobile and aerospace industries in which end high-quality is important. A smoother end can also suggest less want for extra submit-processing, saving time and resources whilst making sure of excessive standards of production quality.

Reduced tools are an immediate consequence of the excessive speeds and precision provided via those spindles. Tools are ultimately longer due to the fact the reducing process is extra efficient and much less abrasive, leading to huge fee financial savings over time. Moreover, whilst tools wear out much less fast, it reduce the frequency of protection and alternatives, lowering downtime and enhancing common productivity.

Applications in Different Industries

High-speed spindles are used in numerous industries, which include aerospace, car, and electronics. For example, a file from Industry Today highlights their vital role in producing excessive-precision automotive elements.

These spindles are important for machining complicated components with stringent tolerances in the aerospace enterprise. The ability to operate at excessive speeds without sacrificing accuracy makes them best for producing intricate components such as turbine blades and structural components. These components frequently have complicated geometries that require particular and efficient machining to ensure overall performance and safety in aerospace packages.

In the automobile quarter, excessive-velocity spindles are used to manufacture engine additives, transmission elements, and different crucial elements that require specific machining. The increased efficiency and stepped forward finish first-rate translate to better-acting vehicles. As car generation advances, the want for high-precision components becomes even more important, and high-pace spindles help meet these stringent necessities.

The electronics industry also benefits from excessive-pace spindle technology. For the manufacturing of tiny, very correct components like circuit boards and semiconductor devices, those spindles are important. The fine tolerances and clean finishes accomplished with excessive-pace spindles are important for the capability and reliability of digital devices. The want for high-pace spindles and different precision machining systems is growing as electronic gadgets get smaller and greater complex.

How to Choose the Right Spindle?

Selecting the best spindle includes considering elements together with spindle speed, electricity, and compatibility with existing machinery. Evaluating the workload and precision requirements of your specific production manner is critical.

Factors to Consider

Spindle velocity: Higher speeds offer quicker slicing however may additionally require greater unique control systems. The pace must match the fabric and the type of machining manner to acquire top-of-the-line results.

Power: Adequate electricity guarantees the spindle can manage the specified workload without overheating. Power is particularly essential while machining tougher substances or appearing tasks that require excessive torque.

Machine Compatibility: Ensure the spindle is well matched along with your present system and manipulate structures. Compatibility with equipment and software programs guarantees seamless integration and maximizes the efficiency of the producing technique.

In addition to these elements, it is also critical to recall the type of fabric being machined. Different materials may additionally require extraordinary spindle speeds and power stages to achieve the favored effects. For instance, substances like aluminum and plastics might also require exceptional spindle settings compared to tougher substances like metal or titanium.

Another consideration is the unique application and the favored final results. For instance, tasks that require excessive precision and fine finishes might also gain from spindles with higher velocity competencies and advanced management features. On the other hand, heavy-responsibility machining operations may additionally require spindles with better electricity and torque to deal with the expanded load.

Maintaining High-Speed Spindles

To ensure excessive-speed spindles’ lifespan and top-rated overall performance, routine renovation is critical. This includes habitual inspections, lubrication, and timely alternatives of worn-out components.

Maintenance Tips

- It is crucial to carry out routine inspections to search for put on or damage. Early hassle diagnosis can save downtime and avoid extra severe conditions.

- Ensure proper lubrication to reduce friction and prevent overheating. Lubrication helps keep smooth operation and extends the lifestyles of the spindle.

- Replace worn or damaged additives promptly to avoid similar damage. Timely alternatives of parts can prevent breakdowns and make certain continuous, dependable operations.

It’s additionally essential to keep your workspace tidy. Dust and particles can damage the spindle and reduce its efficiency, so it is vital to keep the workspace clean and free from contaminants. Investing in the right dirt extraction systems and regularly cleansing the workspace can help guard the spindle and enhance its performance.

In addition to those measures, operators need to comply with the producer’s renovation suggestions and schedules. Adhering to these tips guarantees that the spindle operates within its greatest parameters and minimizes the danger of sudden disasters.

Key Takeaways

- Understanding the position of high-velocity spindles in modern-day production.

- Benefits of the use of high-velocity spindles for manufacturing efficiency.

- Common programs of excessive-speed spindles throughout different industries.

Future of High-Speed Spindle Technology

Advancements in spindle technology are continually shaping the destiny of production. Innovations which include adaptive manipulation algorithms and sensor systems promise to similarly enhance the performance and reliability of high-speed spindles.

The destiny of high-speed spindle generation also includes the development of more energy-green designs. There is a push to reduce the environmental effect of producing tactics and reduce electricity utilization as sustainability turns into an increasing priority in the manufacturing zone. High-speed spindles with advanced energy performance will play a key role in attaining these desires.

In conclusion, excessive-speed spindles are a cornerstone of present-day manufacturing, presenting several benefits that decorate productiveness, precision, and performance. As the era keeps boosting, the skills of high-paced spindles will only enhance, riding further innovations inside the production enterprise and putting new requirements for performance and exceptional.

Read More: The Flower of Veneration Chapter 1